Bend sensors based on nanocellulose composites: Influence of configuration of resistive strain gauge

DOI:

https://doi.org/10.3103/S0735272723090042Keywords:

bend sensor, sensor configuration, nanocellulose, polyvinyl alcohol, biodegradable material, wearable sensorsAbstract

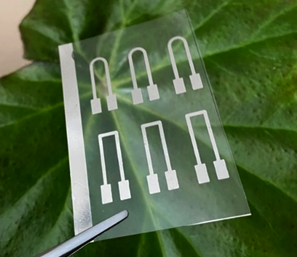

The paper is devoted to studying the influence of the configuration of the tenso-sensitive element on the characteristics of bend sensors manufactured on the basis of nanocellulose (NC) and polyvinyl alcohol (PVA) composites. For this purpose, a suspension of NC was extracted during the oxidation of organosolvent cane cellulose in the medium of reagent 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO). Nanocellulose-based composite materials were obtained by mixing the NC suspension and PVA aqueous solution and vacuuming. The films were produced by pouring the mixture into Petri dishes and drying them in a thermal chamber. Technological masks were manufactured from magnetic material using photochemical etching to set different configurations for the tenso-resistors (U-, Π-, UU-, and ΠΠ-type). A metal strain-sensing element (Ti-Ni) was deposited on the surface of films by reactive magnetron sputtering in the argon medium. The atomic force microscopy (AFM) studied the surface morphology of different substrates. The strain-sensitive characteristics of bend sensors were measured, based on which the coefficients of strain-sensitivity, reversibility, and time drift were calculated. It has been established that the maximum value of strain sensitivity (16.19) occurs for sensors based on the NC–PVA composite with Π-type configuration. At the same time, the best reversibility (0.09%) was observed for sensors with a U-type configuration of the sensitive element. The results indicate the potential of using nanocellulose and PVA composites to develop elastic bend sensors in wearable electronics.

References

- Z. Hong et al., “Welded carbon nanotube–graphene hybrids with tunable strain sensing behavior for wide-range bio-signal monitoring,” Polymers, vol. 16, no. 2, p. 238, 2024, doi: https://doi.org/10.3390/polym16020238.

- A. Javaid et al., “Paper-based wearable ultra-sensitive strain sensors for fitness monitoring,” Flex. Print. Electron., vol. 8, no. 115019, 2023, doi: https://doi.org/10.1088/2058-8585/acc4d7.

- H. M. Dewey, A. Lamb, J. Budhathoki-Uprety, “Recent advances on applications of single-walled carbon nanotubes as cutting-edge optical nanosensors for biosensing technologies,” Nanoscale, 2024, doi: https://doi.org/10.1039/D4NR01892C.

- X. Wang et al., “A highly stretchable carbon nanotubes/thermoplastic polyurethane fiber-shaped strain sensor with porous structure for human motion monitoring,” Compos. Sci. Technol., vol. 168, pp. 126–132, 2018, doi: https://doi.org/10.1016/j.compscitech.2018.09.006.

- A. Ciampaglia, R. Ciardiello, F. Cesano, G. Belingardi, V. Brunella, “Multifunctional material design for strain sensing: Carbon black effect on mechanical and electrical properties of polyamides,” Compos. Struct., vol. 304, p. 116373, 2023, doi: https://doi.org/10.1016/j.compstruct.2022.116373.

- X. Zhu, T. Cui, F. Su, B. He, “Robust polyethylene sensor complex for multi-dimensional monitoring,” Chem. Eng. J., vol. 463, p. 142407, 2023, doi: https://doi.org/10.1016/j.cej.2023.142407.

- Y. Liu, H. Zheng, M. Liu, “High performance strain sensors based on chitosan/carbon black composite sponges,” Mater. Des., vol. 141, pp. 276–285, 2018, doi: https://doi.org/10.1016/j.matdes.2017.12.046.

- V. Lapshuda, V. Koval, V. Barbash, M. Dusheiko, O. Yashchenko, S. Malyuta, “Flexible humidity sensors based on nanocellulose,” in 2022 IEEE 41st International Conference on Electronics and Nanotechnology (ELNANO), 2022, pp. 208–212, doi: https://doi.org/10.1109/ELNANO54667.2022.9927092.

- Z. Candan et al., “Nanocellulose: Sustainable biomaterial for developing novel adhesives and composites,” in Industrial Applications of Nanocellulose and Its Nanocomposites, Elsevier, 2022, pp. 49–137.

- V. Barbash, O. Yaschenko, “Preparation, properties and use of nanocellulose from non-wood plant materials,” in Novel Nanomaterials, London: IntechOpen, 2021.

- V. Koval, V. Barbash, M. Dusheyko, V. Lapshuda, O. Yashchenko, A. Naidonov, “Nickel-based piezoresistive sensors obtained on flexible nanocellulose substrate,” in 2021 IEEE 11th International Conference Nanomaterials: Applications & Properties (NAP), 2021, pp. 1–5, doi: https://doi.org/10.1109/NAP51885.2021.9568610.

- Y. Chen et al., “Recent progress on nanocellulose aerogels: preparation, modification, composite fabrication, applications,” Adv. Mater., vol. 33, no. 11, 2021, doi: https://doi.org/10.1002/adma.202005569.

- V. Lapshuda, V. Koval, M. Dusheiko, V. Barbash, O. Yashchenko, S. Maliuta, “Capacitive and resistive humidity sensors based on flexible nanocellulose film for wearable electronics,” Radioelectron. Commun. Syst., vol. 65, no. 11, pp. 597–608, 2022, doi: https://doi.org/10.3103/S0735272722120019.

- S. Kumar et al., “Contemporary nanocellulose-composites: A new paradigm for sensing applications,” Carbohydr. Polym., vol. 298, p. 120052, 2022, doi: https://doi.org/10.1016/j.carbpol.2022.120052.

- P.-L. Schaefer, G. Chagnon, A. Moreau-Gaudry, “Geometry-based model for U-shaped strain gauges on medical needles,” in 2018 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), 2018, pp. 4269–4272, doi: https://doi.org/10.1109/EMBC.2018.8513310.

- H. Bai, Y. Li, S. Zhang, P. Ma, W. Dong, “Photo-crosslinkable poly (vinyl alcohol)/nanocrystalline cellulose composites with controllable performance and exceptional water vapor barrier property for packaging application,” Cellulose, vol. 29, no. 14, pp. 7721–7734, 2022, doi: https://doi.org/10.1007/s10570-022-04760-x.

- A. Naidonov, V. Koval, V. Barbash, M. Dusheiko, O. Yashchenko, O. Yakymenko, “Nanocellulose-based biodegradable bend sensors,” in 2022 IEEE 41st International Conference on Electronics and Nanotechnology (ELNANO), 2022, pp. 292–297, doi: https://doi.org/10.1109/ELNANO54667.2022.9927070.

- J. Zhou et al., “Highly sensitive and stretchable strain sensors based on serpentine-shaped composite films for flexible electronic skin applications,” Compos. Sci. Technol., vol. 197, p. 108215, 2020, doi: https://doi.org/10.1016/j.compscitech.2020.108215.

- V. A. Barbash, O. V. Yashchenko, A. S. Gondovska, I. M. Deykun, “Preparation and characterization of nanocellulose obtained by TEMPO-mediated oxidation of organosolv pulp from reed stalks,” Appl. Nanosci., vol. 12, no. 4, pp. 835–848, 2022, doi: https://doi.org/10.1007/s13204-021-01749-z.

- A. O. Naidonov, M. H. Dusheiko, V. M. Koval, V. A. Barbash, “Disposable wearable sensors based on nanocellulose for biomedical applications,” Microsystems, Electron. Acoust., vol. 27, no. 3, 2022, doi: https://doi.org/10.20535/2523-4455.mea.264043.